ICPI Certified Installers

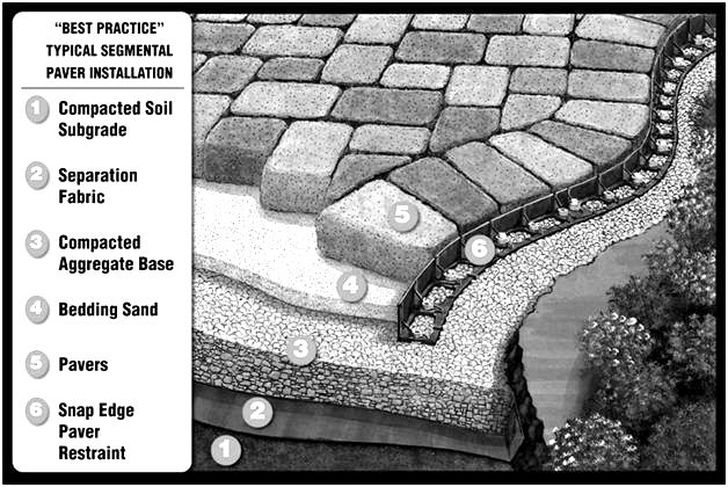

CG Hardscapes is one of the few companies who is certified through the Interlocking Concrete Pavement Institute. It is important to make sure your contractor is ICPI certified so that they are aware of all the aspects of installing a proper flexible pavement system. An ICPI certified installer is on every job and is there to make sure things go smoothly. An ICPI certified installer is essential for larger projects such as outdoor living areas, around pools, fire pits, and kitchens.